The biggest trend in construction right now is designing and building highly efficient homes or even a “Passive House” to reduce our ecological footprint. Most people understand a highly efficient home to simply have the highest R-value materials for insulation. This is not really true.

The biggest trend in construction right now is designing and building highly efficient homes or even a “Passive House” to reduce our ecological footprint. Most people understand a highly efficient home to simply have the highest R-value materials for insulation. This is not really true.

As an example, a “Passive House”

(considered the gold standard of high efficiency) does not require specific R-values. Instead it looks more at how much energy is used per square meter in a year for operating, heating and cooling the house. In order to achieve this standard a lot of other aspects need to be considered, such as passive solar design and landscape, window technology, airtightness, ventilation, space heating, lighting fixtures, electrical appliances and insulation.

In other words, achieving this “Gold Standard” is not as simple as only looking at R-values.

The Canadian building code mainly considers R-values for insulation, which doesn’t really tell you the whole truth about how efficient a building is. Research has proven that a well built log home which only has an R-value of between 6 – 9 will have the same heating and cooling costs as a conventional 2″x6″ stick framed and insulated building with an R-value of 22. In fact, the Canadian building code will accept the R-value of a log house build with a 150 millimeter wide log or bigger.

How can a simple log with such a low R-value be as efficient as a 2″x6″ insulated wall?

The answer is “Thermal mass”

In short, “Thermal mass” is the concept of “inertia” against temperature fluctuations.

For example, when outside temperatures are fluctuating throughout the day, a large thermal mass within the insulated portion of a house can serve to “flatten out” the daily temperature fluctuations, since the thermal mass will absorb thermal energy when the surroundings are higher in temperature than the mass, and give thermal energy back when the surroundings are cooler, without reaching thermal equilibrium. (this statement is from Wikipedia)

If we look at the Trappeur Homes wall design with the Bondu dovetail logs, we do have a very good thermal mass value due to the logs alone. Further, we add 1.5 inches of wood fiber board inside the Bondu Logs which offers an additional high thermal mass value. This 100% recycled wood-fibre board also provides additional insulation, acts as a wind breaker and becomes a complete thermal break (to avoid thermal bridging) between the log wall and inside framed wall.

If we look at the Trappeur Homes wall design with the Bondu dovetail logs, we do have a very good thermal mass value due to the logs alone. Further, we add 1.5 inches of wood fiber board inside the Bondu Logs which offers an additional high thermal mass value. This 100% recycled wood-fibre board also provides additional insulation, acts as a wind breaker and becomes a complete thermal break (to avoid thermal bridging) between the log wall and inside framed wall.

Our standard wall system uses a 2″X4″ inside framed wall and is rated at R-26 which is a bit more then a conventional 2″X6″ stick framed and insulated wall at R-22. With a 2″X6″ inside framed wall our Trappeur Homes wall assembly is rated at R-34 (for those who want more).

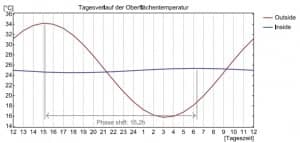

Considering R-Values alone it appears there is not a big difference between our R-26 wall and a stick framed R-22 wall, but have a look at the diagram to the left showing the outside and inside surface temperature changes during the day. The inside surface temperature stays very stable due to a very high heat protection value of 22.3 from the thermal mass giving us a temperature phase shift of 15.2 hours.

Considering R-Values alone it appears there is not a big difference between our R-26 wall and a stick framed R-22 wall, but have a look at the diagram to the left showing the outside and inside surface temperature changes during the day. The inside surface temperature stays very stable due to a very high heat protection value of 22.3 from the thermal mass giving us a temperature phase shift of 15.2 hours.

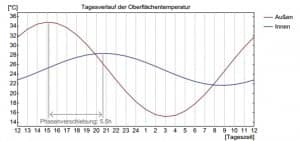

A similar chart on the right shows a conventional 2″X6″ stick framed and insulated wall (R-22). The heat protection value is only 3.0 which gives a temperature phase shift of only 5.5 hours leading to fast and significant inside surface temperature changes. You can see the inside surface temperature is not very stable compared to the above diagram showing the Trappeur Homes wall system (Blue Line).

This explains how the thermal mass in a Trappeur Home helps it stay way cooler in the summer and makes it much more efficient than a conventional stick framed building.

Research reference:

According to our interpretations of information from the Canadian Construction Materials Center and the Model National Energy Code (1997), a 150mm milled log wall need not comply with effective thermal resistance requirements, as trade off calculations for this type of log structure are permitted.

For purposes of trade off calculations, a 150mm milled log wall shall be taken as RSI = 1.3. Round Scribed log walls shall be taken as RSI = 2. SPF, (spruce, pine, fir) as the wood species.

For more complete information, please consult the:

Technical guide for Milled-log Buildings, report 13142 , Milled Log Houses report 13140 (5.2.1) and Model National Energy Code of Canada for Houses (1997) (3.3.1.2)

Canadian Construction Materials Center

Ottawa (Ontario)

Canada K1A 0R6

Other studies conducted in some northern states of the USA showed that R-values may be increased substantially to account for the thermal mass storage and thermal lag of solid wood walls.

In 1991, the NAHB (National Association of Home Builders) Research Center conducted a study for the LHC (Log Homes Council). This study showed that“ the thermal mass of log walls significantly reduces energy use for heating in cold climates. The study compared the actual energy use by eight log homes and eight well insulated foam houses during one winter. The houses were evenly divided between upstate New-York and Montana. The study also compared the home’s actual energy consumption. The results led to the conclusion that log homes are as energy efficient as frame houses, even though the average R-value of the log walls was 44 percent lower than the R-value of the frame walls.

More complete information is available in the:

Research Report on Energy Efficiency of Log Buildings published by the

Log Homes Council National Association of Home Builders

15th & M. Streets, N.W.

Washington, D.C. 20005

USA